Staple Fiber Needlepunched Nonwoven Geotextile Manufacturer For River Bank Protection

1. UV resistant.

2. High temperature resistance to up to 230℃ maintaining structure stability and original physical properties.

3. High flat drainage and vertical permeability.

4. High creep resistance.

5. Resistance of erosion of chemicals in soil as well as thecorrosion of gasoline and diesel etc.

Description:

The non-woven geotextile is made of filament or short fiber laid into a network through different equipment and processes. After needle punched and other processes, different fibers are interwoven and intertwined to make the fabric standardized,soft, full, thick and hard, so as to meet the requirements of different thickness.

The non-woven geotextile has good fabric gap and good adhesion Due to the softness of the fiber, it has certain tear resistance, good deformation adaptability, and good plane drainage capacity. The surface is soft and multi gap, and has a good friction coefficient, which can increase the adhesion capacity of soil particles, prevent the loss of particles by preventing the loss of particles, and eliminate the excess water. The surface is soft and has good protection ability. According to the length of filament, it can be divided into filament non-woven geotextile or short filament non-woven geotextile. They can play a very good filtration, isolation, reinforcement, protection and other effects, is a widely used geosynthetics. The tensile strength of filament is higher than that of staple, so it can be used according to specific requirements.

We offer a wide range of nonwoven geotextiles made of polypropylene fibers, which provide excellent physical and hydraulic properties and are chemically stable in a wide range of environments. Primarily used for subsurface drainage, soil separation, filtration and rockslope protection. These are cost effective economical solutions for many applications, which will withstand installation stresses with high puncture and burst resistance. The high permeability properties provide high water flow rates for excellent filtration properties.

Geotextile Advantages:

1. UV resistant.

2. High temperature resistance to up to 230ºC maintaining structure stability and original physical properties.

3. High flat drainage and vertical permeability.

4. High creep resistance.

5. Resistance of erosion of chemicals in soil as well as thecorrosion of gasoline and diesel etc.

6. High elongation under certain stress, thus able to adapt to uneven and irregular bases.

Product Parameters

(2). Separation, filtration, drainage, reinforcement , protection and maintentance function.

|

Gram weight

|

Thickness(mm)

|

Breaking strength(kn/m)

|

CBR burst strength(KN)

|

Elongation at break(%)

|

Tear Strength (KN)

|

Sieve size O99(O35)mm

|

|

100

|

0.9

|

2.5

|

0.3

|

25-100

|

0.08

|

0.07-2.0

|

|

150

|

1.3

|

4.5

|

0.6

|

25-100

|

0.12

|

0.07-2.0

|

|

200

|

1.7

|

6.5

|

0.9

|

25-100

|

0.16

|

0.07-2.0

|

|

250

|

2.1

|

8.0

|

1.2

|

25-100

|

0.20

|

0.07-2.0

|

|

300

|

2.4

|

9.5

|

1.5

|

25-100

|

0.24

|

0.07-2.0

|

|

350

|

2.7

|

11.0

|

1.8

|

25-100

|

0.28

|

0.07-2.0

|

|

400

|

3.0

|

12.5

|

2.1

|

25-100

|

0.33

|

0.07-2.0

|

|

450

|

3.3

|

14.0

|

2.4

|

25-100

|

0.38

|

0.07-2.0

|

|

500

|

3.6

|

16.0

|

2.7

|

25-100

|

0.42

|

0.07-2.0

|

|

600

|

4.1

|

19.0

|

3.2

|

25-100

|

0.46

|

0.07-2.0

|

|

800

|

5.0

|

25.0

|

4.0

|

25-100

|

0.60

|

0.07-2.0

|

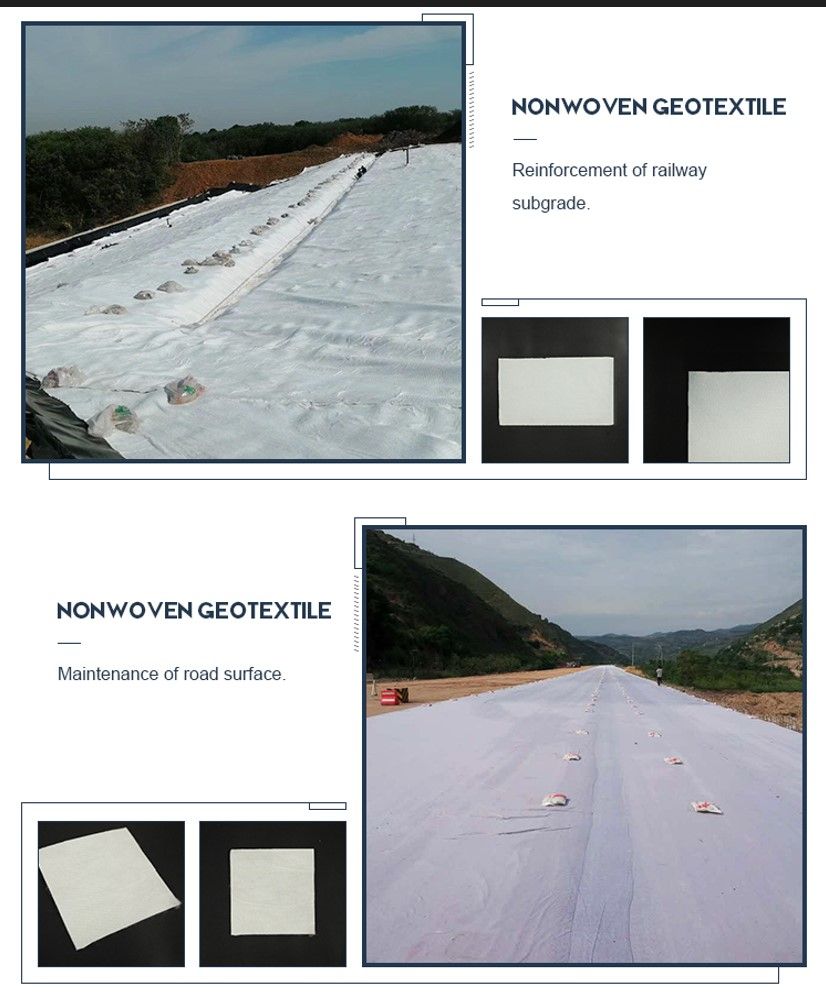

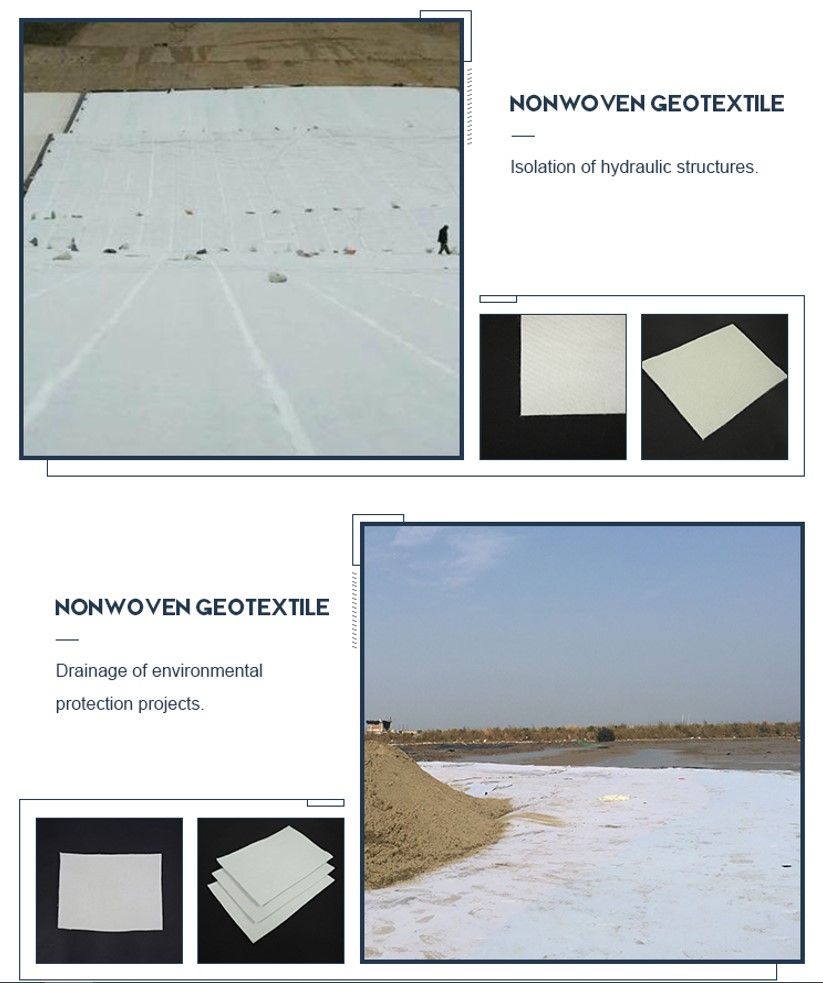

Applications of Geotextiles

1. Drainage

Geotextiles will efficiently collect surplus water from structures, such as rainwater or surplus water, from the soil and

discharge it.

2. Filtration

Our geotextiles provide superior hydraulic flow and soil retention, which makes them well suited for filtration in subsurface

drainage applications and under hard armour systems.

3. Separation

Geotextiles are used for paved and unpaved roads, where ground conditions have been compromised. As a separation layer,geotextiles can aid preventing the intermixing of dissimilar materials, add to the performance life of the road and reduce the overall thickness of the road section by requiring less aggregate during construction.

4. Reinforcement

High strength geotextiles can be used to reinforce earth structures as the strength of the tape or filament within the fabric

maybe increased to suit a specific application. Thanks to their high tensile strength they are an ideal reinforcement solution.

5. Protection

Due to the consistent thickness and weight of our Geotextiles, they provide adequate cushioning and protection for critical lining systems.

FAQ

Q1: Are you a factory or trading company? Where is your company located?

A1: We are a manufacturer/factory. Our company is located in Shandong, China.

Q4:How to get the sample?

we only charge the freight fee. The freight fee will be returned If you place the order.