Hdpe Plastic Geocell Retaining Walls Geocell For Road

Cellular confinement systems (CCS)—also known as geocells—are widely used in construction for erosion control, soil stabilization on flat ground and steep slopes, channel protection, and structural reinforcement for load support and earth retention.Typical cellular confinement systems are geosynthetics made with ultrasonically welded high-density polyethylene (HDPE) strips or novel polymeric alloy (NPA)—and expanded on-site to form a honeycomb-like structure—and filled with sand, soil, rock, gravel or concrete.

Description:

-

Warranty:

-

5 years, More than 5 years

- After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training

- Project Solution Capability:

-

graphic design, 3D model design, total solution for projects

- Application:

-

Earthwork Apllication, Building, Road Basement

- Design Style:

-

Modern

- Place of Origin:

-

Anhui, China

- Brand Name:

-

zhongloo

- Model Number:

-

ZL-TGGS

- Material:

-

HDPE PP

- Color:

-

Black/Yellow/Green/White

- THICKNESS:

-

1.0-1.7mm

- Height:

-

50mm~250mm

- Keyword:

-

Soil Stabilization Geocell Grid

- Surface:

-

Textured Smooth

- WELDING DISTANCE:

-

330mm-1000mm

Supply Ability

- Supply Ability

- 60000 Square Meter/Square Meters per Day

Packaging & Delivery

- Packaging Details Factory low price driveway road slope protection HDPE paving plastic gravel stabilizer geocell manufacturer for sale

- Plastic woven bags for plastic HDPE geocell or according to customer's requirements

- Port qingdao port ; shanghai port; ningbo port or According to customers' requirments

- Picture Example:

-

- Lead Time:

-

Quantity(square meters) 1 - 1 2 - 1000 1001 - 10000 >10000 Est. Time(days) 7 9 11 To be negotiated

Erosion Control for construction and slope protection hdpe Geocell Cellular

Free samples are available.

Products Description

HDPE paving plastic gravel stabilizer geocell basic details:

|

Cell depth

|

50mm ,100mm , 150mm , 200mm , 250mm

|

|

Welding space

|

330mm ~ 1600mm

|

|

Thickness

|

1)1.0mm~1.2mm for smooth geocell

(2) 1.5mm~1.7mm for textured geocell |

1.HDPE Paving Plastic Gravel Stabilizer Geocell Introduction:

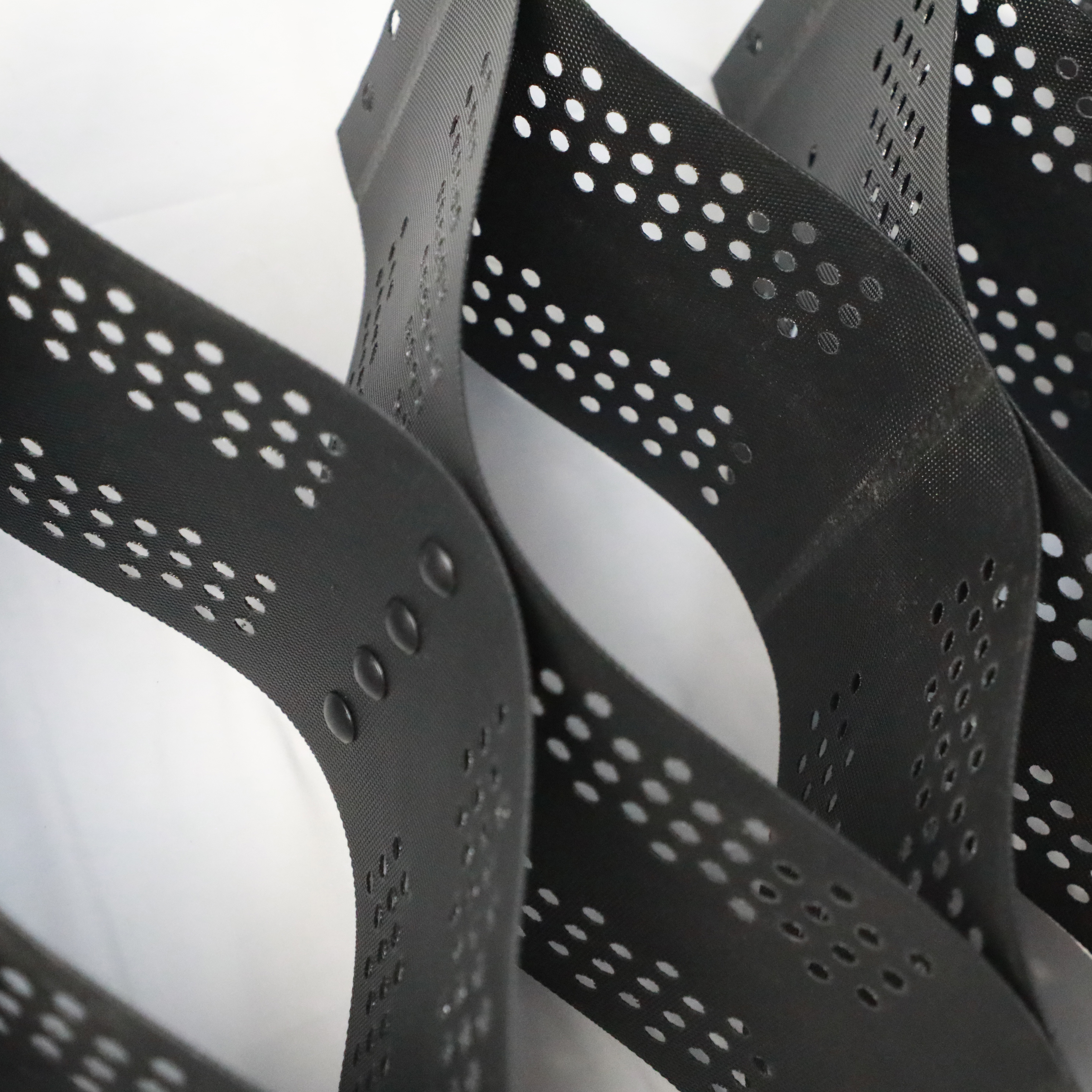

Plastic geocell cellular confinement system is three dimensional , honeycomb like structures manufactured from high density polyethylene and jointly welded by ultrasonic technique . It is flexible to fold during the transport and installation on construction site .The geocell nets will be filled with soils , granular, cements or other on-site infill materials when stretched into web structures , which has powerful and rigid confinement in the lateral and vertical sides .

Plastic geocell cellular confinement system is three dimensional , honeycomb like structures manufactured from high density polyethylene and jointly welded by ultrasonic technique . It is flexible to fold during the transport and installation on construction site .The geocell nets will be filled with soils , granular, cements or other on-site infill materials when stretched into web structures , which has powerful and rigid confinement in the lateral and vertical sides .

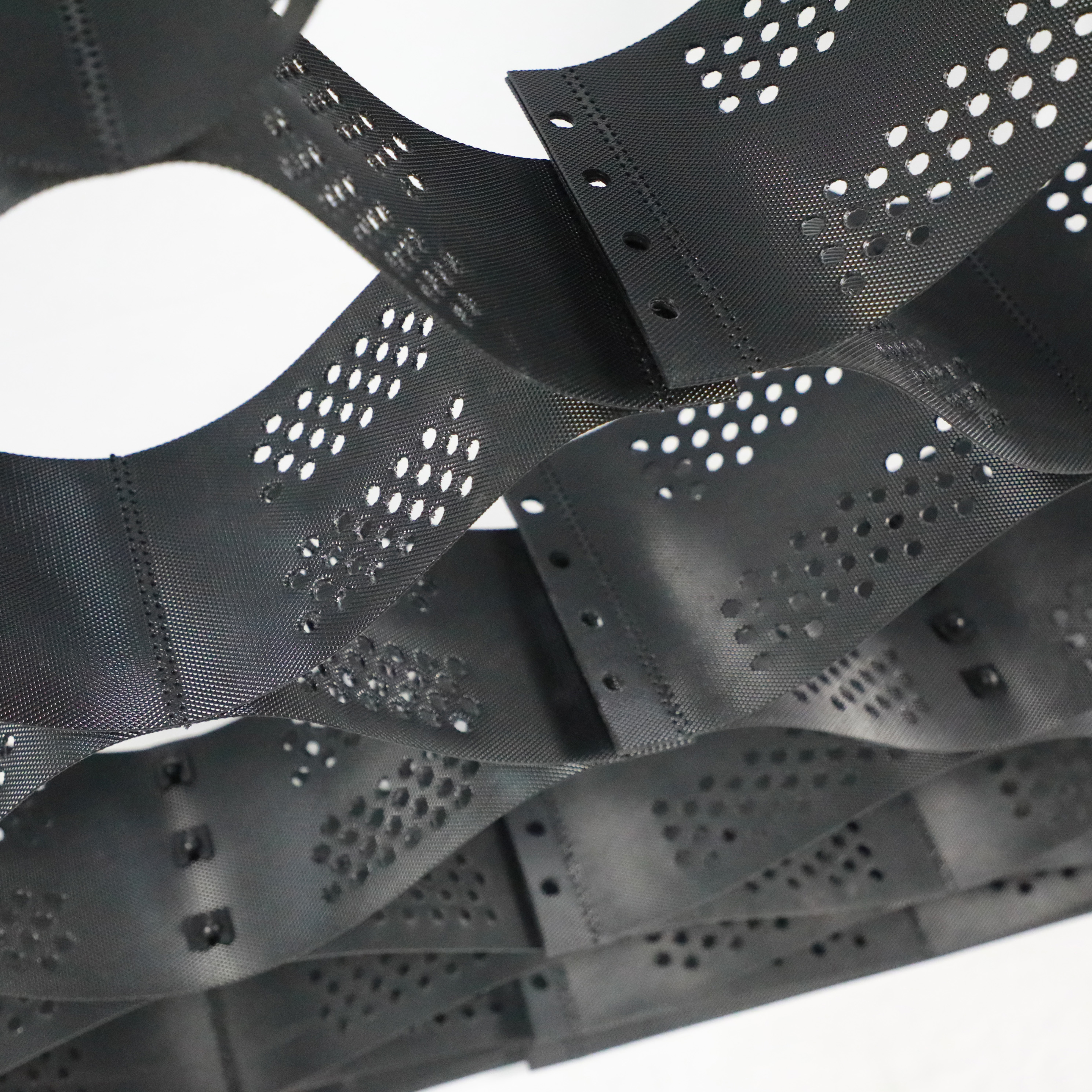

2.HDPE Paving Plastic Gravel Stabilizer Geocell Specifications:

1.Cell depth: 50mm , 100mm , 150mm , 200mm , 250mm

2. Welding space: 330mm~1600mm

3. Thickness: 1.0mm , 1.2mm , 1.5mm , 1.8mm

4. Appearance: smooth / textured

1.Cell depth: 50mm , 100mm , 150mm , 200mm , 250mm

2. Welding space: 330mm~1600mm

3. Thickness: 1.0mm , 1.2mm , 1.5mm , 1.8mm

4. Appearance: smooth / textured

3.HDPE Paving Plastic Gravel Stabilizer Geocell Features:

1) Light material , resistant to wear , stable in chemical properties , anti-aging , resistant to acids and alkalis, applicable to different soil and desert and other geological conditions .

2)High limit on lateral direction , anti-skidding , anti-deformation , effectively enhance the supporting ability and scattered load function of roadbed .

3)High carrying capacity and good dynamic performance and high erosion ability .

4)The geometry size can be changed to meet different needs of the project , such as height and welding distance .

5)Retractable and small loading volume , convenient joint , speed construction .

6)Local material can be used during construction , reduce the construction cost , easy to be transported after folding together .

1) Light material , resistant to wear , stable in chemical properties , anti-aging , resistant to acids and alkalis, applicable to different soil and desert and other geological conditions .

2)High limit on lateral direction , anti-skidding , anti-deformation , effectively enhance the supporting ability and scattered load function of roadbed .

3)High carrying capacity and good dynamic performance and high erosion ability .

4)The geometry size can be changed to meet different needs of the project , such as height and welding distance .

5)Retractable and small loading volume , convenient joint , speed construction .

6)Local material can be used during construction , reduce the construction cost , easy to be transported after folding together .

4.Technical Parameters:

|

Material Properties

|

unit

|

|

|

|

|

Tested Method

|

||

|

Cell Depth

|

mm

|

75

|

100

|

150

|

200

|

|

||

|

Polymer Density

|

g/cm3

|

0.935-0.965

|

ASTM D 1505

|

|||||

|

Enviroment Stress Crack Resistance

|

Hours

|

>400

|

ASTM D 5397

|

|||||

|

Enviroment Stress Crack Resistance

|

Hours

|

6000

|

ASTM D 1693

|

|||||

|

Carbon Black Content

|

%

|

1.5%-2.0%

|

ASTM D 1603

|

|||||

|

Nominal Sheet Thickness Before Texturing

|

mm

|

1.27-5%,+10%

|

ASTM D 5199

|

|||||

|

Nominal Sheet Thickness After Texturing

|

mm

|

1.27-5%,+10%

|

ASTM D 5199

|

|||||

|

Strip Puncture Resistance

|

N

|

450

|

ASTM D 4833

|

|||||

|

Seam Peel Strength

|

N

|

1065

|

1420

|

2130

|

2840

|

EN ISO 13426-1B

|

||

|

Seam Efficiency

|

%

|

GRI100

|

GRI-GS13

|

|||||

|

Norminal Expanded Cell Size(width x length)

|

mm

|

320x287,475x508 etc

|

|

|||||

|

Norminal Expanded Panel Size(width x length)

|

m

|

2.56x8.35,4.5x5.0,6.5x4.5,6.1x2.44

|

|

|||||

5.HDPE paving plastic gravel stabilizer geocell Production &Packing:.

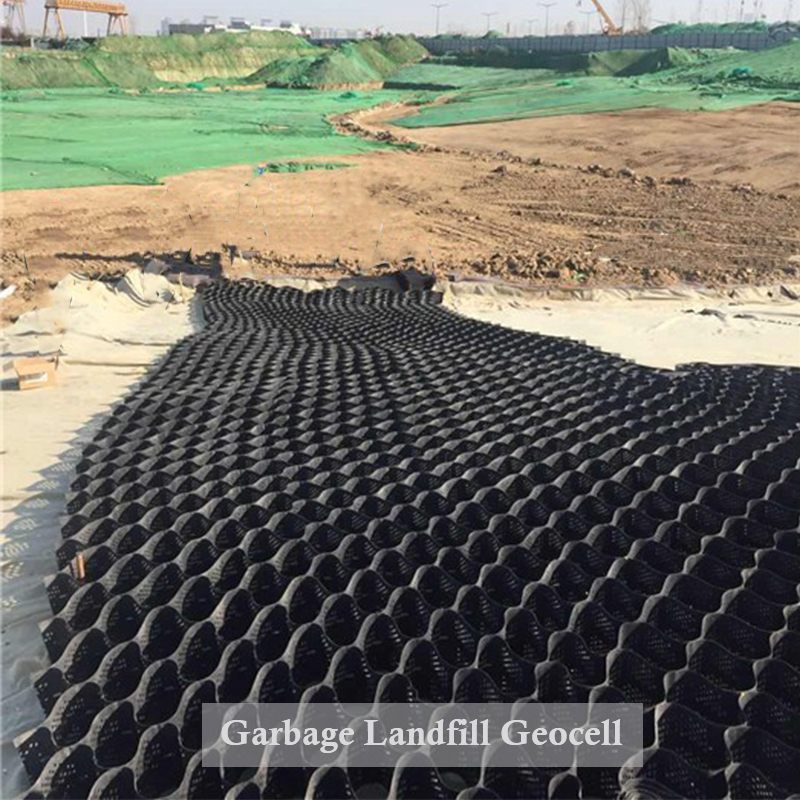

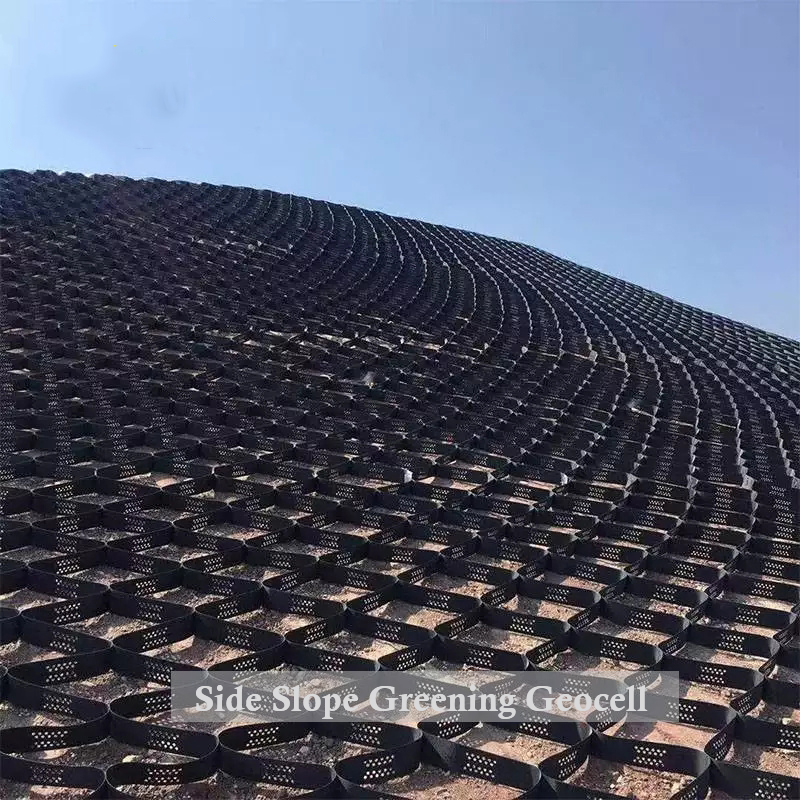

6.Applications:HDPE paving plastic gravel stabilizer geocell

1. Used for all kinds of road building , driveways , soil stabilization and embankment stabilization

2. Used to stabilize river embankments .

3. Used to prevent landslides .

4. Using Geocell construction can greatly reduce labor intensity and reduce the thickness of the roadbed , construction speed ,

good performance and greatly reduce the project cost .

1. Used for all kinds of road building , driveways , soil stabilization and embankment stabilization

2. Used to stabilize river embankments .

3. Used to prevent landslides .

4. Using Geocell construction can greatly reduce labor intensity and reduce the thickness of the roadbed , construction speed ,

good performance and greatly reduce the project cost .

7.HDPE Paving Plastic Gravel Stabilizer Geocell Production: