Fiberglass Geogrid For Highway Airport Runway Railway Slope

1.It is manufactured to ISO 9001 quality standards.

2.It has excellent UV and oxidation resistance and performance is not affected by creep.

3.It is easily milled and recycled and environmentally friendly.

4.It is suitable for use in paving fabric applications.

5.It has a low elongation,extend the life of roads, runways and parking lots and lower maintenance costs.

Description:

Introduction:

The properties of Biaxial Geogrids, made of Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material. The reinforcing action of PP Biaxial Geogrids lies mainly in confining soil and increasing its shearing resistance by a process of interlocking between the square ribs and the soil. The load dispersal effect from the interlocking mechanism is highly effective and can reduce sub-base thickness and construction cost. PP Biaxial Geogrids can be used with any kind of mechanical fill material. Two aperture size ranges are available for optimum matching with project fill.

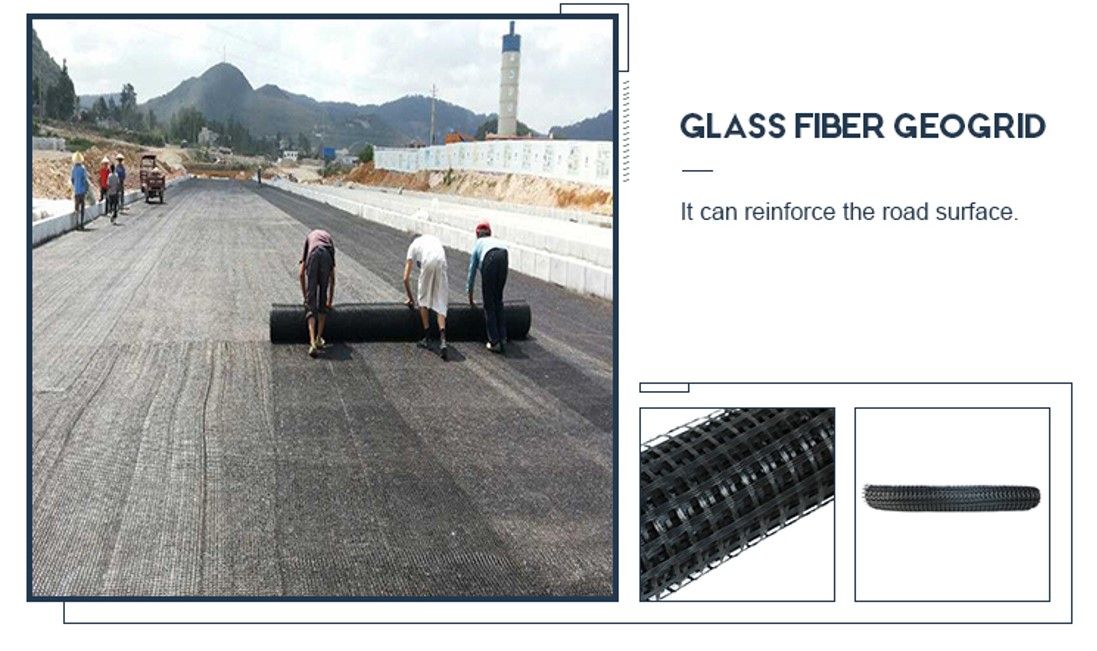

Glass Fiber Geogrid is composed of a reticular structural material made of glass fiber filament with modified bitumen coating. It withstands high and low temperatures and can resist corrosion. FiberGlass geogrid is a stress relief asphalt reinforcement grid developed specifically for ashpalt overlays. Fiber Glass geogrid can not only decrease the cost of construction but also longer the service life of the pavement and road.

Glass Fiber Geogrid in a pavement system can distribute traffic loading of vehicle and prevent reflective cracking due to temperature difference to extend service life of pavement.

Data Sheet

| Property | Test method | TGSB 30-30 | TGSB 40-40 | TGSB 50-50 | TGSB 60-60 | TGSB 70-70 | TGSB 80-80 | TGSB 90-90 | TGSB 100-100 | TGSB 120-120 | TGSB 130-130 | ||

| Ultimate tensile strength | KN/m | MD | EN ISO 10139 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 120 | 130 |

| CD | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 120 | 130 | |||

| Elongation at maximum load | % | MD | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| CD | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |||

| Approximate mesh size | mm | 12-50 | |||||||||||

| Roll width | m | 1-6 | |||||||||||

| Roll length | m | 50-200 | |||||||||||

Features:

The product has the characteristics of high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long life and so on. In engineering fields such as slope protection, road and bridge pavement enhancement treatment, it can strengthen and reinforce the pavement, prevent pavement rutting fatigue cracks, hot-cold expansion cracks and reflection cracks below, and can disperse the bearing stress of the pavement, prolong the service life of the pavement, high Low tensile strength, low elongation, no long-term creep, good physical and chemical stability, good thermal stability, anti-fatigue cracking, high temperature rutting resistance, low temperature shrinkage crack resistance, delay and reduce reflection cracks.

Application:

1. The old asphalt concrete pavement is reinforced to strengthen the asphalt surface layer to prevent diseases.

2. The cement concrete pavement is converted into a composite pavement to suppress reflection cracks caused by plate shrinkage.

3. Road extension and improvement project to prevent cracks caused by the junction of new and old and uneven settlement.

4. Reinforcement treatment of soft soil foundation is conducive to the consolidation of soft soil water separation, effectively inhibits settlement, uniform stress distribution, and enhances the overall strength of the roadbed.

5. The semi-rigid base of the newly built road produces shrinkage cracks, and the reinforcement is reinforced to prevent the pavement cracks caused by the reflection of the base cracks.

FAQ

1, What is the difference between uniaxial and biaxial geogrid?

Biaxial geogrids are those that exhibit the same strength in both the machine directions MD and cross-machine directions CMD while uniaxial geogrids exhibit the primary strength in the machine direction with minimal strength, enough to maintain the aperture structure, in the cross-machine direction.

2, How many types of geogrids are there?

There are three different types of geogrids: Uniaxial, Biaxial, and Triaxial . Each one is designed and manufactured for specific construction applications with various tensile strengths.

3, Are you trading company or manufacturer?

We are factory.

4,Is the quality of your products stable?

The company has a complete QC system, and each batch of products will be sampled and the samples will be kept for 5 years.

5,Can you do OEM?

Yes, of course. We can produce the products as your request.

6, Do you provide samples? is it free?

Yes, we could offer the sample for free charge but do not pay the cost of freight.

7,How long is your delivery time?

Generally it is 5-10 days if the goods are in stock. or it is 10-15 days if the goods are not in stock, it is according to quantity.

8, What is your terms of payment?

Payment<=5000USD, 100% in advance. Payment>=30000USD, 30% T/T in advance,balance before shipment.