Anti-Seepage Composite Geomembrane For Fish Pond Liners

Main Features of Composite Geomembrane:

1.Impermeability: Composite geomembranes provide an effective barrier against the passage of liquids, gases, and contaminants. This impermeability helps to prevent pollution of soil and groundwater, making them ideal for containment applications such as landfill liners, pond liners, and liquid containment systems.

2.Strength and Durability: The combination of geomembrane and geotextile layers in composite geomembranes enhances mechanical strength, puncture resistance, tear resistance, and durability. This ensures long-term performance and stability, even in challenging environmental conditions or when subjected to heavy loads.

3.Chemical Resistance: Composite geomembranes exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, hydrocarbons, and other aggressive substances. This chemical resistance ensures protection against corrosion and degradation, making them suitable for applications involving hazardous materials or chemical containment.

4.Environmental Compatibility: Composite geomembranes are manufactured using materials that are inert, non-toxic, and environmentally friendly. They do not leach harmful chemicals into the surrounding soil or water, making them safe for use in sensitive environmental areas and for applications requiring compliance with environmental regulations.

Description:

Description:

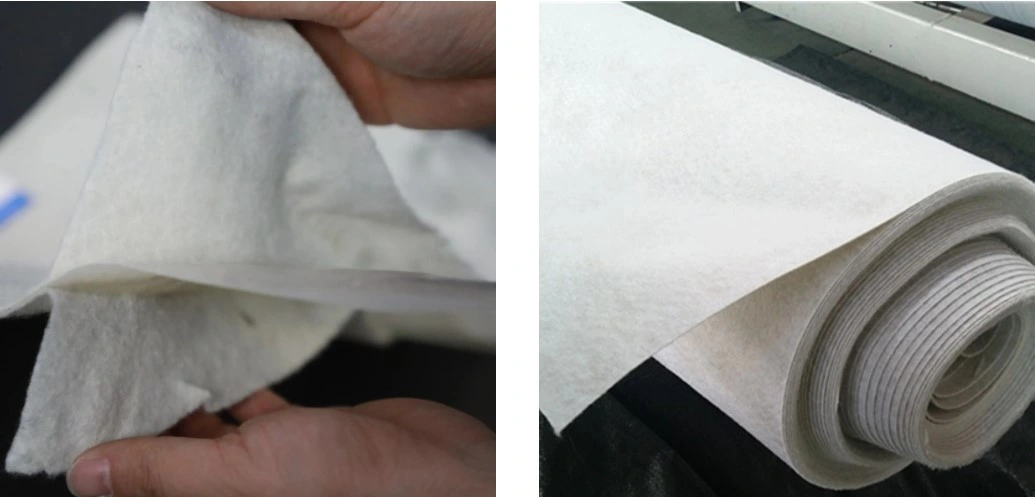

Composite geomembrane is a kind of impervious material compounded of geotextile and geomembrane.

It has many types: one textile one membrane, two textiles one membrane, many textiles many membranes and so on. Composite geomembrane is mainly used for drainage and reinforcement, has the advantages of acid and alkali-resistance, good infiltration-resistance, pull-resistance, tearing-resistance, hi -bursting strength and so on,mainly for waterpfoor purpose.

Composite Geomembrane Liner provides the advantages of both geotextiles and geomembranes. The geotextile layer increases essential tensile strength and the geomembranes provides excellent impermeable, leak, moisture proof and tear and puncture resistance.The main role a composite geomembrane liner has for a municipal solid waste system for landfills is that is reduces the amount of leakage through small seep holes that sometimes form in the Geomembrane part of the geocomposite liner. Our composite geomembrane liner is widely used for landfills, waste water treatment, roads construction, aquaculture, landscape and agriculture, etc

Composite Geomembrane Liner is made by heat-bonding nonwoven or woven geotextile combined with HDPE geomembranes by calendaring processing technology. composite geomembrane liner is automatically formed by pressing one or two geotextile layer to the geomembrane layer in the continuous far infrared ray heating oven, polymer and anti-aging materials are added in the production process at the same time, so it can be used in unconventional temperature environment.

The composite geomembrane liner provides the advantages of both geotextiles and geomembranes. The geotextile layer increases essential tensile strength and the geomembranes provides excellent impermeable, leak, moisture proof and tear and puncture resistance. Our composite geomembrane liner are widely used for landfills, waste water treatment, roads construction, aquaculture, landscape and agriculture, etc.

Products Specification

Technical Parameters of compound geomembrane |

||||||||

| Product weight G/M2 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | |

| SPEC |

1 layer geotextile +1 layer membrane | 150/0.25 |

200/0.3 |

300/0.3 |

300/0.4 |

300/0.5 |

400/0.5 |

400/0.6 |

| 2 layer geotextile +1 layer membrane | 100/0.2/100 | 100/0.3/100 | 150/0.3/150 | 200/0.3/200 | 200/0.4/200 | 200/0.5/200 | 250/0.5/250 | |

| Breaking strength (kN/m) | 5.0 | 7.5 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 | |

| Elongation at break (%) | 300~100 | |||||||

| CBR Mullen burst strength (KN) | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | |

| Vertical permeability coefficient (CM/S) | K*10-11~13 | |||||||

| Hydraulic pressure (MPa) | 0.4~0.6 | 0.6~1.0 | ||||||

Features

- High tensile strength and tearing strength

- Excellent seepage control, seepage prevention and moisture proof performance

- Excellent chemical resistance

- High strength, anti puncture

- High friction coefficient, excellent wear resistance

- Excellent UV resistance

- Stable low temperature resistance to brittleness

- Anti-aging and anticorrosion

- Easy to deploy efficiently

- Cost saving

Having the functions and advantages of both geotextiles and geomembranes, composite geomembrane products are widely used for environmental protection, traffic facilities, roads construction, aquaculture, water resources protection, municipal projects and mining industry, etc al.

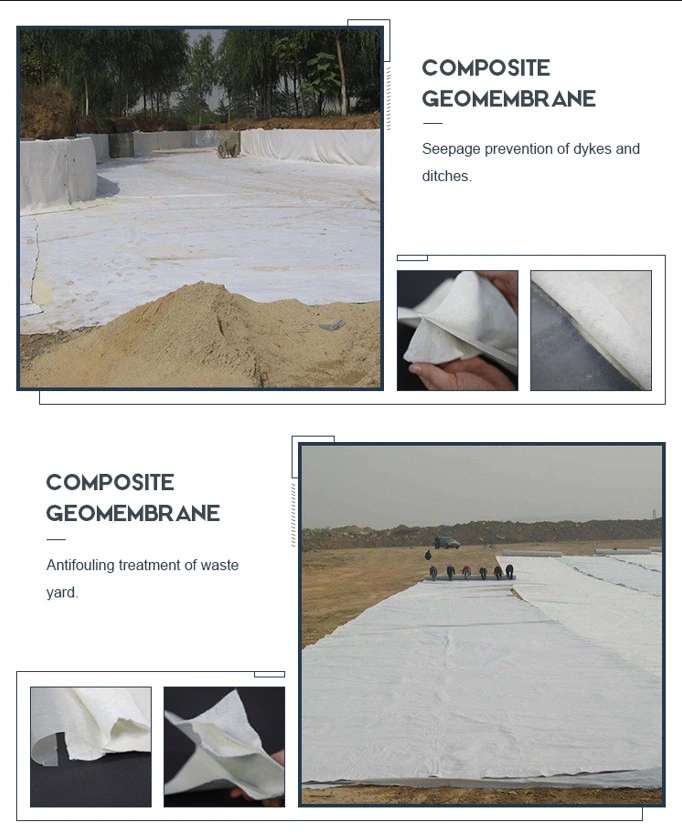

- Environmental protection. Landfills, sewage treatment plant, solid waste containment of industrial and hospital, etc.

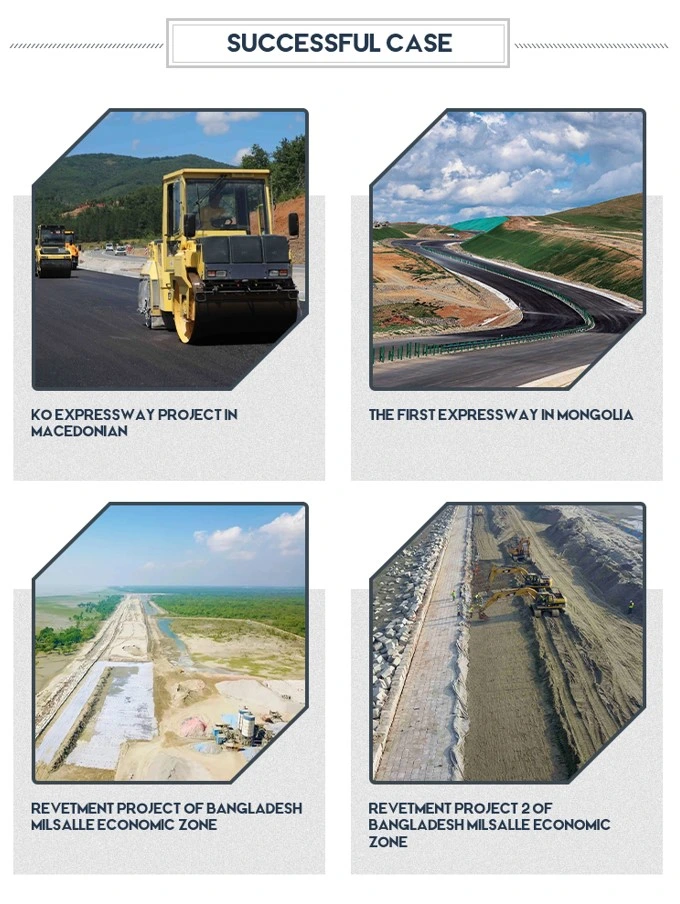

- Traffic facilities. Road or airport foundation reinforcement, anti-seepage of subway and culvert, etc.

- Aquaculture. Anti-seepage of ditch, channel, reservoir, drinking water tank, pool, irrigation system and fish, shrimp farms, etc.

- Water resources protection. Anti-seepage leakage blockage and reinforcement of river, lake, reservoir, bank, anti-seepage of canal, side slope, etc.

- Municipal projects. Subway and underground engineering structures , anti-seepage of plantation roof and roof garden, lining of sewage pipe, etc.

- Mining industry. Anti-seepage of ash field, dissolving tanks, yard pile and tailings, etc

(1)Service:

A. OEM/ODM orders are warmly welcome

B. All of our products have proceeded testing before shipment and we guaranteed the good quality.

(2) Quality Control:

We have established a national-standard laboratory for in-house quality control and built a strict quality control system in all aspects from raw materials testing and production processes to final product quality testing.

Not only is stringent internal quality control carried out at zhonglu, but regular testing and analyzing of our product performance is implemented by authoritative testing organizations in Europe and the United States.

FAQ

What is geosynthetics ?

Geosynthetics form a perfect erosion control fabric used extremely widely in civil engineering to stabilize and reinforce slopes and soil under or next to roads, railways, dams, water reservoirs etc.. They can be easily applied which minimizes the time of construction, as well as they limit the resources and materials necessary.

What kinds of geosynthetics we have ?

Non-woven geotextile, geogrids, geocells, GCL, Geomembranes, Geonets, Geocomposites etc .

What is the geosynthetics used for ?

Hydraulic

Lagooning and Water Treatment, Ornamental Ponds, Golf Courses

Aquaculture and Desalination,Water Lagoons,Tanks, Reservoirs, Liquid Waste,Floating Cover Solutions, Drainage and Filtration

Environment

Tailing ponds, Leach mining,Landfills,Landfill Capping,Protection against corrosion,Vertical Barriers

Civil Works

Erosion Control,Secondary Containment,Tunnels,Linear and Surface Works,Consolidation of Margins,Soil Reinforcement,Soil Separation.

Building - Parkings,Roofing,Soundproofing

Professional geosynthetics manufacturer

Anhui Zhonglu Engineer Materials Co., Ltd

Angela:86-18095658976